Search This Supplers Products:Caustic SodaActivated CarbonCalcium ChlorideAFFFDioctyl PhthalateSodium Tripolyphosphate

- Home

- About us

- Products

- Caustic Soda

- Activated Carbon

- Calcium Chloride

- AFFF

- Polymerization Aluminum

- Sodium Sulphate

- Formic Acid

- Sodium Bicarbonate

- Dioctyl Phthalate

- Anthracite Filter Media

- Sodium Tripolyphosphate

- Sulfur Coated Urea

- Sodium Hydroxide

- Sodium Hydrosulphide

- Soda Ash Light

- Silicon Dioxide

- Carbon Black

- Ceramic Ball

- LABSA

- Chemical Auxiliary Agent

- Detergent Raw Materials

- Nitrogen Fertilizer

- Chemical Fertilizer

- Pharmaceutical Intermediates

- CAC2

- Organic acids

- Faqs

- News

- anthracite filter media

- sodium tripolyphosphate

- sodium hydrosulphide

- polymerization of aluminum

- caustic soda

- ammonium nitrate

- calcium chloride

- sodium sulphate

- sodium bicarbonate

- soda ash light

- Silicon Dioxide

- carbon black

- activated carbon

- sodium hydroxide

- LABSA

- formic acid

- Dioctyl phthalate

- Urea

- AFFF

- Certificate

- Contact us

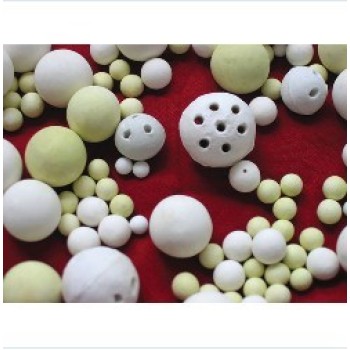

Inert alumina ceramic ball

- group name

- Ceramic Ball

- Min Order

- 1 piece

- brand name

- KS

- update time

- Thu, 05 Jul 2012 00:44:43 GMT

Packging & Delivery

-

Min Order1 piece

Briefing

2.higher milling efficiency

3.ideal grinding ball in ceramic industry

Detailed

Place of Origin: China (Mainland) | Type: Ceramic Balls | Application: Industrial Ceramic |

Material: Alumina Ceramic | Colour: White |

|

Packaging & Delivery

Packaging Detail: | Standard export packing: Plastic Woven bag+ pallet,1x20'' container can load 25ton. |

Delivery Detail: | 1 week for 1*20GP |

Specifications

Ceramic ball as abrasive media, it is a grinding body used in ball mill

Hardness: 9

Density: 3.62

Size(mm): 10 20 30 40 50 60

Ceramic ball as abrasive media:

The products are featured by high hardness, big density, low wear lost, good normalizations, good corrosion-resistance etc. They are the most ideal high-efficient grinding media for milling glaze materials, and various powdered ore. They are using ceramics, cements, paints, refractory, inorganic mineral powders and other materials to form.

Features:

1. High wear-resisting: The alumina balls wear resisting is higher than the common ceramic balls. When it is working, the ball will not pollute the grinded materials, so it can keep the purity and improve the stability of grinded materials especially the ceramic glaze.

2. High density: the high density, high hardness and the high grinding characters save the grinding time, enlarge the smashing room. So It can improve the grinding efficiency.

Index for alumina grinding balls:

Product

| Al2O3 (%) | Density (g/cm3) | Water absorption (%)

| Mohs hardness (scale)

| Abrasion loss (%) |

75 series |

75 |

≥3.25 |

≤0.02 | 8-8.5

| ≤0.01

|

92 series | 92 | ≥3.65 | ≤0.02 | 9 | ≤0.011 |

|

|

|

|

|

|

|

|

|

|

|

|

The standard specification of alumina ceramic grinding ball:

Diameter (mm) | φ25 | φ30 | φ40 | φ50 | φ60 | φ70 |